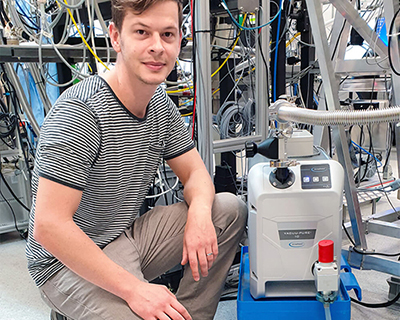

Clemens Todt conducts exciting research at the Swiss Federal Institute of Technology in Zurich (ETH), where he is a doctoral student in the Laboratory of Solid State Physics.

Why is cryopump regeneration so important?

Clemens Todt: Our high purity plants are absolutely “sacred”. Our defects in the crystal lattice are 1013 per 1024 atoms per cubic centimeter. So we have eleven orders of magnitude before we find an atom, which we don’t want. When the cryopump is regenerated, contaminants from the fore vacuum pump can enter the system, such as moisture from the air, oil, abrasion. When the chamber is back in a high vacuum state, we can detect the contaminants with a mass spectrometer. We want to avoid these contaminations with absolutely clean fore pumps.

How was VACUU·PURE able to succeed?

Clemens Todt: Before using it on our sensitive plant, we investigated whether the VACUU·PURE screw pump could be used in our plant. For the regeneration of our cryogenic pumps, we were looking for a robust and high-purity vacuum pump: this must have a base pressure of at least 10-2 mbar. In addition, a sufficiently high pumping speed is required to cope with the escaping gases from the cryopump. Of course, it is also essential that it is completely oil and particle free.

VACUU·PURE met all the requirements. We tested the pump on a cryogenic pump on a test chamber. The screw pump handled the amount of argon gas without seizing. In addition, we could see in the mass spectrometer that it did not bring oil or other hydrocarbons or abrasion into the system. Therefore, we subsequently added the new vacuum pump to the actual “sharp” magnetron sputtering system.

Are there any other special features of VACUU·PURE?

Clemens Todt: The beauty of VACUU·PURE is that it is a small compact cube. We can easily move the vacuum pump from A to B for our various applications. Then just plug it in, turn it on, and we’re done.

Do you use VACUU·PURE for other tasks?

Clemens Todt: We use it to purge the high-purity gas supply system of the magnetron sputtering system. To do this we pump down the line to the screw pump’s base pressure of 10-3 mbar, fill to just above atmospheric pressure with argon, and pump down again. We do this whole thing a couple of times. In addition, VACUU·PURE is also used on the UHV systems to generate the rough vacuum.

Advantages of VACUU·PURE® 10C

- Ultimate vacuum of 10-3 mbar

- Pumping speed of 10 m3/h

- 100% oil-free, without hydrocarbons

- Abrasion-free, without particles

- Ideal for regeneration of cryopumps

- Suitable for pumping light gases such as argon

- Compact design

How is the cooperation with VACUUBRAND?

Clemens Todt: I like to tell people that my main job is active problem solving. (Laughs) A good example is finding the right vacuum pump to regenerate the cryogenic pumps. Fortunately, I never had any problems with VACUUBRAND – the pumps just run. The products have proven themselves for us. For example, we already use many of their diaphragm pumps. With the VACUU·PURE screw pump, we have now added a great new product to our equipment.

Would you like more information about cryopump regeneration or any vacuum application? Please contact us