Lyophilisation

Systems by Martin Christ (Germany), commonly known as freeze dryers are deployed in various applications due to their ability to preserve and stabilise sensitive materials by removal of water through the process of sublimation. As the most prominent brand, our systems play a crucial role in the pharmaceutical industry by enabling the production of stable and long -lasting pharmaceutical products, diagnostics, and research materials that would otherwise be sensitive to temperature and moisture. The applications we serve include Vaccine Production, Drug Formulation and Development, API’s, Parenteral Formulations (i.e. Injectables), Biologics and Protein Therapeutics, Diagnostic Kits and lets not forget fundamental or applied research. Freeze Drying is a valuable tool in research laboratories for studying the effects of freeze-thaw cycles on drug stability, developing new formulations and analysing the impact of lyophilisation on various pharmaceutical products.

Lyophilisation Trays, Cups and Lyoprotect® Membranes

Teclen have developed a unique technology in designing containers for the lyophilization of API. The key to their technology is the inert and naturally hydrophobic ePTFE Lyoprotect® Membrane, which is your shield against contamination, keeping particles and airborne germs at bay. It keeps your product securely contained, eliminating any possibility of fly-out or loss. At the same time, vapor can escape smoothly during sublimation.

With the Lyoprotect® technology, there is a significant reduction of dust exposure when compared to open containers. It prevents cross-contamination in your freeze dryer, eliminating the need for a cleaning validation between different batches, and ensures optimum protection of product and operators.

Lyoprotect® containers for sterile freeze drying are available in choices of material, offering single-use and multiple-use options. All components, including the membrane, can be sterilised in an autoclave – thus APIs can be produced aseptically in compliance with GMP. Trays are also customisable in size to perfectly fit the footprint of your individual freeze-dryer, allowing perfect shelf utilisation and optimised capacity.

Solvent Evaporation and Concentration

Rotary concentrators and centrifugal evaporators are essential tools in chemistry labs using vacuum to evaporate solvents at moderate temperatures. Rotary evaporators utilize a rotating flask, under vacuum, in a temperature-controlled bath to efficiently evaporate solvents. The precise control of vacuum pressure and bath temperature enable fast solvent removal while preserving delicate samples. Centrifugal concentrators employ rapid spinning to enhance solvent evaporation from multiple samples in a batch. Typically, samples are presented to the system in vials or test tubes after a purification step. Both devices use vacuum for the concentration of solutions at moderate temperatures, streamlining processes and enhancing productivity in the modern chemistry laboratory.

We supply rotary evaporators from Heidolph and Genser with options from basic – but high-quality – to fully automated systems that fill and empty automatically. Sizes range from compact benchtop to floor-standing models. Our centrifugal concentrators are from Genevac and available in a number of different versions to suit users. Genevac offer unique technologies such as their DriPure system which protects from sample cross contamination. The new EZ2 Bionic is perfect for high throughput laboratories looking for automated loading of the concentrator.

In the pharmaceutical industry, wiped film evaporators play a crucial role in various processes involved in drug development, manufacturing, and quality control. The AG Concentration range consists of Thin Film and Short Path Evaporators (otherwise known as wiped film evaporators). The PTFE rotor blades form a uniform film over a heated column. Thin film formation under low pressure reduces the boiling point and hydrostatic pressure of chemical components. This results in evaporation of volatile fractions at low temperatures. The wiper motion also pushed the film downwards and reduces the retention time on its heated surface. Therefore, the thin film and short path evaporators are highly suitable for concentration/distillation of temperature-sensitive chemical mixtures, enzymes, proteins, vitamins, aromatic compounds, botanicals, and more. Broadly speaking, aside from concentration and solvent removal, purification and fractional distillation, other uses include process optimisation and scale-up studies which is essential for ensuring feasibility and efficiency of larger scale processes.

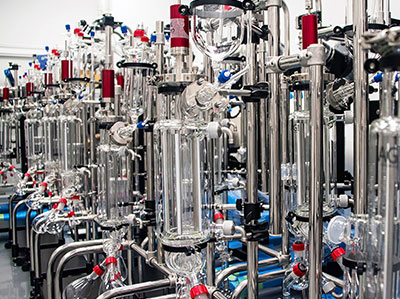

Stirred Reactors

Systems by Radleys (The UK) and Asahi Glassplant (Japan) play a central role in pharmaceutical science applications due to their versatility and controllability. They can be deployed during various stages of drug development, and are a indispensable tool for achieving consistent and high-quality pharmaceutical products. Common applications we have serviced include Crystallisation (where supersaturation and crystallisation kinetics can be controlled), Chemical Synthesis to make intermediates or APIs (where advanced sensors with control loops keep control over common parameters like pH, temp, mixing), Polymerisation and many others. Partnered with our pioneering technology Thermostats by Huber (Germany); we’ve got ALL your reaction conditions covered.

Calorimetry

Instruments we offer from Setaram (France) that are widely used for the analysis of drug stability and compatibility studies. The technique precisely measures the heat flow associated with temperature-induced transitions in a sample, or specifically to investigate the thermal behaviour of drugs and their formulations.

Our team of experienced and tertiary educated specialists are here to support your enquiry in providing consultative, personal service where and when you need it. We are proud of our role we service in the pharmaceutical industry and passionate about the solutions we can offer, and we’re conveniently located in major cities throughout Australia and New Zealand.